北京康拉德科技有限公司

张敏

手 机:

STEARNS PART NO. 64423160951Q 刹车

PART NO. 64423160951Q刹车秒报价Hurst 3002-005电机

Hurst 3202-003电机

Hurst LYG55T115EL76S电机

Hurst 3402-007电机

Hurst 2602-015电机

Hurst LYG55T115EL76S电机

metabo GE710 直磨机

Carpanelli DP63a2/8 三相异步变极电机 DP 2/8 极

Carpanelli DP63a4/8 三相异步变极电机 DP 2/8 极

Carpanelli DP71a2/8 三相异步变极电机 DP 2/8 极

Carpanelli DP80a2/8 三相异步变极电机 DP 2/8 极

Carpanelli DP80b2/8 三相异步变极电机 DP 2/8 极

?SartoLab?, д.о.о., Бранкова

23/II, Београд важе?и

ИНСТИТУТ ЗА НУКЛЕАРНЕ НАУКЕ "ВИНЧА"

Назив:

РЕГИСТАР ИЗДАТИХ СЕРТИФИКАТА

БИРО ЗА СЕРТИФИКАЦИ?У Област: Ех уре?а?и Година: 2009. Страна: 19 од 20

Ред.

бр.

БРО?

СЕРТИФИКАТА

ДАТУМ

ИЗДАВА?А

РОК / УСЛОВИ

ВАЖЕ?А

СЕРТИФИКАТА

НАЗИВ ПРОИЗВОДА ПРОИЗВО?АЧ (назив и адреса) ПОДНОСИЛАЦ ЗАХТЕВА СТАТУС СЕРТИФИКАТА

145. VINCA.EX.09.S142 25.12.200 9 Без ограниче?а Напо?на ?единица за ?Sartorius“ ваге (1 ком.) (Power Supply) Тип: YPS02-X DR Фаб.бр.: 2350145 ?Sartorius AG?, Weender Landstrasse 94-108, Goettingen, Немачка ?SartoLab?, д.о.о., Бранкова 23/II, Београд важе?STEARNS PART NO. 64423160951Q 刹车秒报价и

146. VINCA.EX.09.S169 30.12.200 9 Без ограниче?а

Трансмитер притиска (2 ком.)

(UniTrans-IS Pressure Transmitter) Тип:

IUT-10/ IUT-10-A-BBH-GD-ZMTAAL-1Z

PART NO. 64423160951Q刹车秒报价Фаб.бр.:5687738 и 568773

WIKA Alexander Wiegand SE

& Co. KG, AlexanderWiegand-Stra?e

30,

Klingenberg, Немачка

?Термоинже?еринг? д.о.о.,

Мило?а ?ака 2, Београд важе?и

147. VINCA.EX.09.S170 30.12.200 9 Без ограниче?а

Отпорни термометар са трансмитером

(2 ком.) (Температурна сонда) Тип:

TR10-B (Трансмитер: Т24.10)

Сер.бр.трансмитера: 55Е2600233540

и 55Е260023361

WIKA Alexander Wiegand SE

& Co. KG, AlexanderWiegand-Stra?e

30,

Klingenberg, Немачка

?Термоинже?еринг? д.о.о.,

STEARNS PART NO. 64423160951Q 刹车

Hurst 3002-005电机

Hurst 3202-003电机

Hurst LYG55T115EL76S电机

Hurst 3402-007电机

Hurst 2602-015电机

STEARNS PART NO. 64423160951Q 刹车秒报价Hurst LYG55T115EL76S电机

Мило?а ?ака 2, Београд важе?и

metabo GE710 直磨机

Carpanelli DP63a2/8 三相异步变极电机 DP 2/8 极

Carpanelli DP63a4/8 三相异步变极电机 DP 2/8 极

Carpanelli DP71a2/8 三相异步变极电机 DP 2/8 极148. VINCA.EX.09.S171 30.12.200 9 Без ограниче?а Магнетни прекидач за индикатор нивоа (4 ком.) Тип: BGU-A-E Фаб.бр.: -

?KSR Kuebler NiveauMesstechnik

AG?, Im

Kohlstatterfeld 17,

Zwingenberg, Немачка

?Термоинже?еринг? д.о.о.,

Мило?а ?ака 2, Београд важе?и

149. VINCA.EX.09.T001 9.2.2009 3 године (до 08.02.2012.)

Трофазни асинхрони кавезни

електромотор / Three Phase

Asynchronous Electric Motor With Cage

Rotor Тип: 1.SZKT315 S-2

?ATB SEVER?, а.д.

Магнетна по?а 6, Суботица

?ATB SEVER?, а.д. Магнетна

по?а 6, Суботица важе?и

150. VINCA.EX.09.T003 2.4.2009 3 године Висе?а свети?ка Тип: AB 14

?ATX? s.a. EIN 35, rue Andre

Durouchez, Amiens Cedex 2,

Француска

?MLS ExING? д.о.о.,

Трсте?акова 3, Београд важе?и

151. VINCA.EX.09.T004 U 6.10.2009 3 године Пролазни изолатор Тип: MPI VN 12- 6600; MPI VN 16-11000 ?МЕТАЛ? д.о.о., Петра Никола?еви?а-Молера бб, Топола ?МЕТАЛ? д.о.о., Петра Никола?еви?а-Молера бб, Топола важе?и

152. VINCA.EX.09.T005 27.07.200 9 3 године

Tрёхфазный асинхронный

электродвигатель с клеточным

ротором / Three Phase Asynchronous

Electric Motor With Cage Rotor,

Тип/Type: 2.SRZKIT 423 L-6

?ATB SEVER?, Суботица ?ATB SEVER?, Суботица важе?и

STEARNS PART NO. 64423160951Q 刹车秒报价

Hurst 3002-005电机

Hurst 3202-003电机

Hurst LYG55T115EL76S电机

Hurst 3402-007电机

Hurst 2602-015电机

Hurst LYG55T115EL76S电机

153. VINCA.EX.09.T006 24.06.200 9 3 године

Tрёхфазный асинхронный

электродвигатель с клеточным

ротором / Three Phase Asynchronous

Electric Motor With Cage Rotor,

Тип/Type: 1.SZK 225 M-2B

?ATB SEVER?, Суботица ?ATB SEVER?, Суботица важе?и

ИНСТИТУТ ЗА НУКЛЕАРНЕ НАУКЕ "ВИНЧА"

Назив:

metabo GE710 直磨机

Carpanelli DP63a2/8 三相异步变极电机 DP 2/8 极

Carpanelli DP63a4/8 三相异步变极电机 DP 2/8 极

Carpanelli DP71a2/8 三相异步变极电机 DP 2/8 极РЕГИСТАР ИЗДАТИХ СЕРТИФИКАТА

БИРО ЗА СЕРТИФИКАЦИ?У Област: Ех уре?а?и Година: 2009. Страна: 20 од 20

Ред.

бр.

БРО?

СЕРТИФИКАТА

ДАТУМ

ИЗДАВА?А

РОК / УСЛОВИ

ВАЖЕ?А

СЕРТИФИКАТА

НАЗИВ ПРОИЗВОДА ПРОИЗВО?АЧ (назив и адреса) ПОДНОСИЛАЦ ЗАХТЕВА СТАТУС СЕРТИФИКАТА

154. VINCA.EX.09.T007 U 6.10.2009 3 године Пролазни изолатор Тип: MPI ..., (15,16,25,63,100,125,160,200,250, 315,400) ?МЕТАЛ? д.о.о., Петра Никола?еви?а-Молера бб, Топола ?МЕТАЛ? д.о.о., Петра Никола?еви?а-Молера бб, Топола важе?и

155. VINCA.EX.09.T008 U 6.10.2009 3 године

Кабловска уводница, Тип: KTU... [(Re..,

(13,5,16,21,29,36, 42); M..x2;

(64,80,95,100)]; KU... [(Re..,

(7,9,11,13,5,16,21,29,36, 42); M..x1,5;

(12,16,20,25,32,40, 50,63); M..x2;

(64,80,95,100)]

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

важе?и

156. VINCA.EX.09.T009 U 6.10.2009 3 године

Чеп, Тип: ?... [(Re..,

(7,9,11,13,5,16,21,29,36,42); M..x1,5;

(12,16,20,25,32,40,50, 63); M..x2;

(64,80,95,100)]

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

ТополаOlaer LAC2-007-4-D-00-000-0-0 散热器?

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

важе?и

157. VINCA.EX.09.T012 6.10.2009 3 године

Кабловска уводница Тип: KTU... [(Re..,

(13,5,16,21,29,36,42); M..x2; (64,80,95)]

KU... [(Re..,

(7,9,11,13,5,16,21,29,26,42); M..x1,5;

(12,16,18,20,22,28,36,45,55)

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

важе?и

158. VINCA.EX.09.T013 6.10.2009 3 године

Чеп Тип: ?... [(Re..,

(7,9,11,13,5,16,21,29,36,42); M..x1,5;

(12,16,18,20,22,28,36,45,55); M..x2;

(64,80,95,100)]

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

Топола

?МЕТАЛ? д.о.о., Петра

Никола?еви?а-Молера бб,

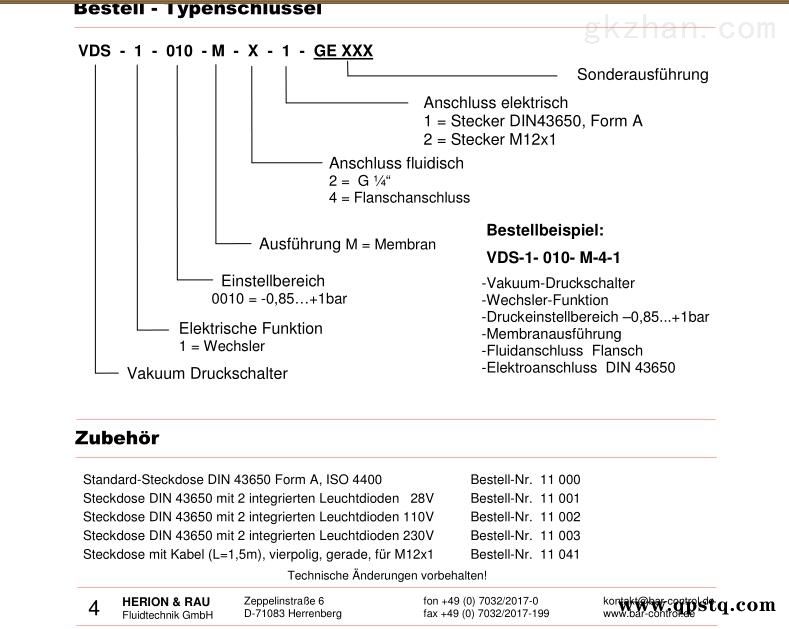

Тополаbarcontrol best.-nr. DS 5901 cat no. VDS-1-010-M-4-1 压力开关

264 | Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich

Manometri e vuotometri interamente in INOX

Gauges and vacuum gauges complete INOX MXX Manometer und Vakuummeter vollst?ndig Edelstahl

Dati tecnici manometri a secco attacco radiale (serie MXX82)

Gauges bottom connection technical data (MXX82 series)

Technischen Daten der Manometer radial Angriff (Serie MXX82)

Applicazioni

Adatti per tutti gli impieghi dove esistono processi corrosivi.

Tutte le applicazioni particolari (attacchi, quadranti, scale non

normalizzate) possono essere risolte dalle nostre officine. Ampia

disponibilità di magazzino.

Descrizione

Manometro costruito secondo Norme UNI EN 837.1 TUTTO

INOX cassa AISI 304 IP65 dn 63 - 100 mm. Perno e movimento

in AISI 316 attacco RADIALE (ISO 228 ).

Per d63: trasparente in policarbonato, quadrante in alluminio fondo

bianco scala BAR ,nera e PSI rossa (doppia scala esclusi mano

vuotometri) Classe di precisione 2,5 - 1,6% - Lancetta in Alluminio.

Per d100: trasparente in vetro stratificato di sicurezza, con tappo

posteriore di sicurezza scala in BAR classe di precisione 1.0% –

lancetta in alluminio micrometrica aggiustabile.

Temperatura d’esercizio

Ambiente -30 / +65 °C

Processo -40 / +180 °C

Pressione d’esercizio

Costante 75% - Variabile 60% - Sovrapressione 25% fino a 60

bar, 15% oltre

Varianti d63

Scale Normalizzate: Vuotometro -1 / 0 Bar+CmHg; Manovuotometro

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo Bar;

0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Varianti d100

Scale Normalizzate: -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9;

-1+15; 1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600;

1000; 1600 bar

Opzioni prodotto

Filetto NPT ANSI B.1.20.1 con o senza glicerina, Sgrassatura uso

ossigeno, scale e/o attacchi personalizzati, loghi, settori colorati,

vetro di sicurezza (d100), esecuzione SOLID FRONT (d100), separatori

(d100), contatti elettrici (d100), attacco radiale ad ore 3/9/12.

Applications

Suitable for corrosive process gas or liquid. With liquid filled case for

applications with high dynamic pressure pulsations or vibrations.

Chemical/petrol-chemical, power stations, mining, on- and

offshore, environmental technology, mechanical engineering and

plant construction. Our workshop is able to solve all your request.

Description

All stainless steel pressure gauge made according UNI EN 837.1

norms case AISI 304 dial 63-100 mm. Stainless steel AISI 316

movement and pivot BOTTOM (ISO 228 ) connection.

For d63: - Aluminum dial White background Black BAR scale

and Red PSI one (double scale except compoud gauge) -

Accuracy 2,5, 1,6% - Aluminum index.

For d100: safety glass window with back blow out cap,

aluminum dial white background black BAR scale, accuracy

1.0% - Micrometric adjustable aluminum index.

Working temperature

Environment -22 / +149 °F

Process -40 / +356 °F

Working pressure

Steady 75% - Variable 60% - Overpressure 25% until 60 bar, 15%

over

Variants d63

Normalized scale: gauge compound -1 / 0 Bar+CmHg; Water

pressure gauge -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Variants d100

Normalized scale: -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15;

1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600; 1000;

1600 bar

Product options

NPT ANSI B.1.20.1 thread, With or without glycerine, OXYGENE

SERVICE customize range, scale or logo; Colored sector; SAFETY

glass, SOLID FRONT production, radial connection 3/9/12

hours.

Anwendungen

Geeignet für alle Anwendungen, bei denen es korrosiven Prozessen.

Alle spezielle Anwendungen (Ports, Zifferbl?tter, Skalen

Nicht-Standard) k?nnen von unseren Workshops gel?st werden.

Die weite Verfügbarkeit von Lager.

Beschreibung

Gebaut nach UNI EN 837,1, komplett Edelstahl AISI 304 IP65

Geh?use DN 63 bis 100 mm. Stift und Bewegung in AISI 316,

RADIAL Angriff (ISO 228 ).

Für d63: aus transparentem Polycarbonat, AluminiumZifferblatt

mit wei?em Hintergrund, Ma?stab BAR schwarz

und rot PSI (zwei Skalen Vakuummeter ausgeschlossen). Genauigkeitsklasse

2,5 bis 1,6%, - Aluminium Hand.

Für d100: transparent VSG, mit Kappe posterionre Sicherheit,

Skalierbarkeit BAR, Genauigkeitsklasse 1,0% - hand Aluminium

Feineinslung.

Betriebstemperatur

Umwelt -30 / +65 ° C

Prozess -40 / +180 ° C

Betriebsdruck

Konstant 75% - Variable 60% - 25% überdruck bis 60 bar, mehr

als 15%

Varianten D63

Ma?stab normalisierten Vakuummeter -1 / 0 Bar+CmHg; Mano-Vakuummeter

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 nur

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Varianten D100

Ma?stab normalisierten -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9;

-1+15; 1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600;

1000; 1600 bar

Produkt-Optionen

Gewinde NPT ANSI B.1.20.1 mit oder ohne Glycerin, Entfetten

Verwendung Sauerstoff, Treppen Angriffen e7o individuelle

Logos, farbige Einheiten, Sicherheitsglas (d100), l?uft SOLID

FRONT (d100), Abscheider (d100), elektrische Kontakte (d100),

Stunden 3/9/12 Stunden.

Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich | 265

fittings solutions MXX

Manometri e vuotometri interamente in INOX

Gauges and vacuum gauges complete INOX

Manometer und Vakuummeter vollst?ndig Edelstahl

MXX 82 Manometri a secco attacco radiale

Gauges bottom connection

Manometer radial Angriff

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX826314099R 63 -1 ÷ 0 G1/4 CL1.6 1

MANOMETRI - GAUGES - Manometer

MXX826314Z06R 63 0 ÷ 0.6 G1/4 CL1.6 1

MXX826314001R 63 0 ÷ 1 G1/4 CL1.6 1

MXX826314106R 63 0 ÷ 1.6 G1/4 CL1.6 1

MXX826314205R 63 0 ÷ 2.5 G1/4 CL1.6 1

MXX826314004R 63 0 ÷ 4 G1/4 CL1.6 1

MXX826314006R 63 0 ÷ 6 G1/4 CL1.6 1

MXX826314010R 63 0 ÷ 10 G1/4 CL1.6 1

MXX826314016R 63 0 ÷ 16 G1/4 CL1.6 1

MXX826314025R 63 0 ÷ 25 G1/4 CL1.6 1

MXX826314040R 63 0 ÷ 40 G1/4 CL1.6 1

MXX826314060R 63 0 ÷ 60 G1/4 CL1.6 1

MXX826314100R 63 0 ÷ 100 G1/4 CL1.6 1

MXX826314160R 63 0 ÷ 160 G1/4 CL1.6 1

MXX826314250R 63 0 ÷ 250 G1/4 CL1.6 1

MXX826314400R 63 0 ÷ 400 G1/4 CL1.6 1

MXX826314600R 63 0 ÷ 600 G1/4 CL1.6 1

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX821012099R 100 -1 ÷ 0 G1/2 CL1.0 1

MANOVUOMETRO - COMPOUND - Manometer

MXX821012115R 100 -1 ÷ 1.5 G1/2 CL1.0 1

MXX821012903R 100 -1 ÷ 3 G1/2 CL1.0 1

MXX821012905R 100 -1 ÷ 5 G1/2 CL1.0 1

MXX821012909R 100 -1 ÷ 9 G1/2 CL1.0 1

MANOMETRI - GAUGES - Manometer

MXX821012Z06R 100 0 ÷ 0.6 G1/2 CL1.0 1

MXX821012001R 100 0 ÷ 1 G1/2 CL1.0 1

MXX821012106R 100 0 ÷ 1.6 G1/2 CL1.0 1

MXX821012205R 100 0 ÷ 2.5 G1/2 CL1.0 1

MXX821012004R 100 0 ÷ 4 G1/2 CL1.0 1

MXX821012006R 100 0 ÷ 6 G1/2 CL1.0 1

MXX821012010R 100 0 ÷ 10 G1/2 CL1.0 1

MXX821012016R 100 0 ÷ 16 G1/2 CL1.0 1

MXX821012025R 100 0 ÷ 25 G1/2 CL1.0 1

MXX821012040R 100 0 ÷ 40 G1/2 CL1.0 1

MXX821012060R 100 0 ÷ 60 G1/2 CL1.0 1

MXX821012100R 100 0 ÷ 100 G1/2 CL1.0 1

MXX821012160R 100 0 ÷ 160 G1/2 CL1.0 1

MXX821012250R 100 0 ÷ 250 G1/2 CL1.0 1

MXX821012400R 100 0 ÷ 400 G1/2 CL1.0 1

MXX821012600R 100 0 ÷ 600 G1/2 CL1.0 1

MXX821012Z00R 100 0 ÷ 1000 G1/2 CL.1.0 1

Codice/Code ? Scala (bar) Attacco “ Precisione

Range Connection” Accuracy

63 10 31 62 66 54 G1/4 14 0.136

100 28 59 101 110 86 G1/2 22 1

? A B D D1 H G” CH Kg

266 | Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich

Dati tecnici manometri a secco attacco posteriore (serie MXX83)

Gauges back connection technical data (MXX83 series)

Technischen Daten der Manometer zuruck Angriff (Serie MXX83)

Applicazioni

Adatti per tutti gli impieghi dove esistono processi corrosivi.

Tutte le applicazioni particolari (attacchi, quadranti, scale non

normalizzate) possono essere risolte dalle nostre officine.

Ampia disponibilità di magazzino.

Descrizione

Manometro costruito secondo Norme UNI EN 837.1 TUTTO INOX

cassa AISI 304 IP65 dn 63 mm trasparente in policarbonato.

Perno e movimento in AISI 316 attacco POSTERIORE (ISO228).

Quadrante in alluminio fondo bianco scala BAR nera e PSI rossa

(doppia scala esclusi mano vuotometri).

Classe di precisione 2,5 - 1,6% - Lancetta in Alluminio.

Temperatura d’esercizio

Ambiente -30 / +65 °C

Processo -40 / +180 °C

Pressione d’esercizio

Costante 75% - Variabile 60%

Sovrappressione 25% fino a 60 bar, 15% oltre

Varianti

Scale Normalizzate: Vuotometro -1 / 0 Bar+CmHg; Manovuotometro

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo Bar;

0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Opzioni prodotto

Filetto NPT ANSI B.1.20.1 con o senza glicerina, sgrassatura uso

ossigeno, scale e/o attacchi personalizzati, loghi, settori colorati.

Applications

Suitable for corrosive process gas or liquid. With liquid filled

case for applications with high dynamic pressure pulsations or

vibrations. Chemical/petrol-chemical, power stations, mining,

on- and offshore, environmental technology, mechanical engineering

and plant construction. Our workshop is able to solve

all your request.

Description

Pressure gauge made according UNI EN 837.1 norms Stainless

steel case AISI 304 dial 63 mm.

BRASS movement and pivot BACK (ISO 228) connection - Aluminum

dial White background Black BAR scale and Red PSI one

(double scale except compoud gauge).

Accuracy 2,5, 1,6% - Aluminum index.

Working temperature

Environment -22 / +149 °F

Process -40 / +356 °F

Working pressure

Steady 75% - Variable 60%

Overpressure 25% until 60 bar, 15% over

Variants d63

Normalized scale: gauge compound -1 / 0 Bar+CmHg; Water

pressure gauge -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Product options

NPT ANSI B.1.20.1 thread, With or without glycerine, OXYGEN

SERVICE, customize range, Scale or logo; Colored sector.

Anwendungen

Geeignet für alle Anwendungen, bei denen es korrosiven Prozessen.

Alle spezielle Anwendungen (Ports, Zifferbl?tter, Skalen

Nicht-Standard) k?nnen von unseren Workshops gel?st werden.

Die weite Verfügbarkeit von Lager.

Beschreibung

Gebaut nach UNI EN 837,1, komplett Edelstahl AISI 304 Geh?use

IP65 dn 63 mm. Stift und Bewegung in AISI 316, ZURüCK (ISO

228) Angriff, transparentem Polycarbonat, Aluminium-Zifferblatt

mit wei?em Hintergrund, Ma?stab BAR schwarz und rot PSI

(zwei Skalen Vakuummeter ausgeschlossen). Genauigkeitsklasse

2,5 bis 1,6%, Aluminium Hand.

Betriebstemperatur

Umwelt -30 / +65 ° C

Prozess -40 / +180 ° C

Betriebsdruck

Konstant 75% - Variable 60%

überdruck bis 60 bar, mehr als 15%

Varianten D63

Ma?stab normalisierten Vakuummeter -1 / 0 Bar+CmHg; Mano-Vakuummeter

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 nur

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Produkt-Optionen

Gewinde NPT ANSI B.1.20.1 mit oder ohne Glycerin, Entfetten

Verwendung Sauerstoff, greift Treppen und/oder individuelle

Logos, farbigen Sektoren.

MXX 83 Gauges back connection

Manometer zuruck Angriff

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX836314099P 63 -1 ÷ 0 G1/4 CL1.6 1

MANOMETRI - GAUGES - Manometer

MXX836314001P 63 0 ÷ 1 G1/4 CL1.6 1

MXX836314106P 63 0 ÷ 1.6 G1/4 CL1.6 1

MXX836314205P 63 0 ÷ 2.5 G1/4 CL1.6 1

MXX836314004P 63 0 ÷ 4 G1/4 CL1.6 1

MXX836314006P 63 0 ÷ 6 G1/4 CL1.6 1

MXX836314010P 63 0 ÷ 10 G1/4 CL1.6 1

MXX836314016P 63 0 ÷ 16 G1/4 CL1.6 1

MXX836314025P 63 0 ÷ 25 G1/4 CL1.6 1

MXX836314040P 63 0 ÷ 40 G1/4 CL1.6 1

MXX836314060P 63 0 ÷ 60 G1/4 CL1.6 1

MXX836314100P 63 0 ÷ 100 G1/4 CL1.6 1

MXX836314160P 63 0 ÷ 160 G1/4 CL1.6 1

MXX836314250P 63 0 ÷ 250 G1/4 CL1.6 1

MXX836314400P 63 0 ÷ 400 G1/4 CL1.6 1

Codice/Code ? Scala (bar) Attacco “ Precisione

Range Connection” Accuracy

63 29 62 68 56 G1/4 14 0.109

? B D D1 H G” CH Kg

Manometri a secco attacco posteriore

Manometri e vuotometri interamente in INOX

Gauges and vacuum gauges complete INOX MXX Manometer und Vakuummeter vollst?ndig Edelstahl

Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich | 267

fittings solutions

Dati tecnici manometri a secco attacco posteriore con flangia 3 fori (serie MXX84)

Gauges back connection with 3 holes flange technical data (MXX84 series)

Technischen Daten der Manometer zuruck Angriff mit Paneelring (Serie MXX84)

Applicazioni

Adatti per tutti gli impieghi dove esistono processi corrosivi.

Tutte le applicazioni particolari (attacchi, quadranti, scale non

normalizzate) possono essere risolte dalle nostre officine. Ampia

disponibilità di magazzino.

Descrizione

Manometro costruito secondo Norme UNI EN 837.1 TUTTO

INOX cassa AISI 304 IP65 dn 63 mm trasparente in policarbonato.

Perno e movimento in AISI 316 attacco POSTERIORE con

FLANGIA (ISO 228). Quadrante in alluminio fondo bianco scala

BAR nera e PSI rossa (doppia scala esclusi mano vuotometri).

Classe di precisione 2,5 - 1,6% - Lancetta in Alluminio

Temperatura d’esercizio

Ambiente -30 / +65 °C

Processo -40 / +180 °C

Pressione d’esercizio

Costante 75% - Variabile 60%

Sovrappressione 25% fino a 60 bar, 15% oltre

Varianti

Scale Normalizzate: Vuotometro -1 / 0 Bar+CmHg; Manovuotometro

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo Bar; 0,6; 1; 1,6;

2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315; 400 Bar + Psi

Opzioni prodotto

Filetto NPT ANSI B.1.20.1 - Sgrassatura uso ossigeno, scale e/o

attacchi personalizzati, loghi, settori colorati.

Applications

Suitable for corrosive process gas or liquid. With liquid filled case

for applications with high dynamic pressure pulsations or vibrations.

Chemical/petrol-chemical, power stations, mining, on- and

offshore, environmental technology, mechanical engineering and

plant construction. Our workshop is able to solve all your request.

Description

All stainless steel pressure gauge made according UNI EN 837.1

norms case AISI 304 dial 63 mm. Stainless steel AISI 316 movement

and pivot BACK (ISO 228) connection with panel

FLANGE - Aluminum dial White background Black BAR scale

and Red PSI one (double scale except compoud gauge)

Accuracy 2,5, 1,6% - Aluminum index

Working temperature

Environment -22 / +149 °F

Process -40 / +356 °F

Working pressure

Steady 75% - Variable 60%

Overpressure 25% until 60 bar, 15% over

Variants

Normalized scale: gauge compound -1 / 0 Bar+CmHg; Water

pressure gauge -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo Bar; 0,6;

1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315; 400 Bar + Psi

Product options

NPT ANSI B.1.20.1 thread, With or without glycerine, OXYGENE

SERVICE customize range, scale or logo; Colored sector.

Anwendungen

Geeignet für alle Anwendungen, bei denen es korrosiven Prozessen.

Alle spezielle Anwendungen (Ports, Zifferbl?tter, Skalen

Nicht-Standard) k?nnen von unseren Workshops gel?st werden.

Die weite Verfügbarkeit von Lager.

Beschreibung

Gebaut nach UNI EN 837.1, komplett Edelstahl AISI 304

Geh?use IP65 dn 63 mm. Stift und Bewegung in AISI 316, ZURüCK

(ISO 228). Angriff mit Frontring, transparentem Polycarbonat,

Aluminium-Zifferblatt mit wei?em Hintergrund, Ma?stab BAR

schwarz und rot PSI (zwei Skalen Vakuummeter ausgeschlossen).

Genauigkeitsklasse 2,5 bis 1,6%, - Aluminium Hand

Betriebstemperatur

Umwelt -30 / +65 ° C

Prozess -40 / +180 ° C

Betriebsdruck

Konstant 75% - Variable 60%

überdruck bis 60 bar, mehr als 15%

Varianten

Ma?stab normalisierten Vakuummeter -1 / 0 Bar+CmHg; ManoVakuummeter

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 nur Bar; 0,6;

1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315; 400 Bar + Ps

Produkt-Optionen

Gewinde NPT ANSI B.1.20.1 mit oder ohne Glycerin, Entfetten

Verwendung Sauerstoff, greift Treppen und/oder individuelle

Logos, farbigen Sektoren.

MXX 84 Manometri a secco attacco posteriore flangia 3 fori

Gauges back connection with 3 holes flange

Manometer zuruck Angriff mit Paneelring

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX846314099F 63 -1 ÷ 0 G1/4 CL1.6 1

MANOMETRI - GAUGES - Manometer

MXX846314001F 63 0 ÷ 1 G1/4 CL1.6 1

MXX846314106F 63 0 ÷ 1,6 G1/4 CL1.6 1

MXX846314205F 63 0 ÷ 2,5 G1/4 CL1.6 1

MXX846314004F 63 0 ÷ 4 G1/4 CL1.6 1

MXX846314006F 63 0 ÷ 6 G1/4 CL1.6 1

MXX846314010F 63 0 ÷ 10 G1/4 CL1.6 1

MXX846314016F 63 0 ÷ 16 G1/4 CL1.6 1

MXX846314025F 63 0 ÷ 25 G1/4 CL1.6 1

MXX846314040F 63 0 ÷ 40 G1/4 CL1.6 1

MXX846314060F 63 0 ÷ 60 G1/4 CL1.6 1

MXX846314100F 63 0 ÷ 100 G1/4 CL1.6 1

MXX846314160F 63 0 ÷ 160 G1/4 CL1.6 1

MXX846314250F 63 0 ÷ 250 G1/4 CL1.6 1

MXX846314400F 63 0 ÷ 400 G1/4 CL1.6 1

Codice/Code ? Scala (bar) Attacco “ Precisione

Range Connection” Accuracy

63 29 62 83 56 G1/4 14 0.153

? B D D1 H G” CH Kg

MXX

Manometri e vuotometri interamente in INOX

Gauges and vacuum gauges complete INOX

Manometer und Vakuummeter vollst?ndig Edelstahl

268 | Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich

Dati tecnici manometri glicerina attacco radiale (serie MXX92)

Gauges liquid fillable bottom connection technical data (MXX92 series)

Technischen Daten der Manometer Glycerin radial Angriff (Serie MXX92)

Applicazioni

Adatti per tutti gli impieghi dove esistono processi corrosivi.

Tutte le applicazioni particolari (attacchi, quadranti, scale non

normalizzate) possono essere risolte dalle nostre officine. Ampia

disponibilità di magazzino.

Descrizione

Manometro costruito secondo Norme UNI EN 837.1 TUTTO

INOX cassa AISI 304 IP65 dn 63 - 100 mm. Perno e movimento

in AISI 316 attacco RADIALE (ISO 228).

Per d63: trasparente in policarbonato, quadrante in alluminio fondo

bianco scala BAR, nera e PSI rossa (doppia scala esclusi mano

vuotometri). Classe di precisione 2,5 - 1,6% Lancetta in Alluminio;

Per d100: trasparente in vetro stratificato di sicurezza, con tappo

posteriore di sicurezza scala in BAR classe di precisione 1.0% –

lancetta in alluminio micrometrica aggiustabile.

Temperatura d’esercizio

Ambiente -30 / +65 °C

Processo -40 / +180 °C

Pressione d’esercizio

Costante 75% - Variabile 60% - Sovrapressione 25% fino a 60

bar, 15% oltre

Varianti d63

Scale Normalizzate: Vuotometro -1 / 0 Bar+CmHg; Manovuotometro

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo Bar;

0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Varianti d100

Scale Normalizzate: -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9;

-1+15; 1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600;

1000; 1600 bar

Opzioni prodotto

Filetto NPT ANSI B.1.20.1 con o senza glicerina, Sgrassatura uso

ossigeno, scale e/o attacchi personalizzati, loghi, settori colorati,

vetro di sicurezza (d100), esecuzione SOLID FRONT (d100), separatori

(d100), contatti elettrici (d100), attacco radiale ad ore 3/9/12.

Applications

Suitable for corrosive process gas or liquid. With liquid filled

case for applications with high dynamic pressure pulsations or

vibrations. Chemical/petrol-chemical, power stations, mining,

on- and offshore, environmental technology, mechanical engineering

and plant construction. Our workshop is able to solve

all your request.

Description

All stainless steel pressure gauge made according UNI EN 837.1

norms case AISI 304 dial 63-100 mm. Stainless steel AISI 316

movement and pivot BOTTOM (ISO 228) connection.

For d63: - Aluminum dial White background Black BAR scale

and Red PSI one (double scale except compoud gauge) - Accuracy

2,5, 1,6% - Aluminum index.

For d100: safety glass window with back blow out cap, aluminum

dial white background black BAR scale, accuracy 1.0% -

Micrometric adjustable aluminum index.

Working temperature

Environment -22 / +149 °F

Process -40 / +356 °F

Working pressure

Steady 75% - Variable 60% - Overpressure 25% until 60 bar, 15%

over

Variants d63

Normalized scale: gauge compound -1 / 0 Bar+CmHg; Water

pressure gauge -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 solo

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Variants d100

Normalized scale: -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15;

1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600; 1000;

1600 bar

Product options

NPT ANSI B.1.20.1 thread, With or without glycerine, OXYGENE

SERVICE customize range, scale or logo; Colored sector; SAFETY

glass, SOLID FRONT production, radial connection 3/9/12

hours.

Anwendungen

Geeignet für alle Anwendungen, bei denen es korrosiven Prozessen.

Alle spezielle Anwendungen (Ports, Zifferbl?tter, Skalen

Nicht-Standard) k?nnen von unseren Workshops gel?st werden.

Die weite Verfügbarkeit von Lager.

Beschreibung

Gebaut nach UNI EN 837.1, komplett Edelstahl AISI 304 Geh?use

IP65 dn 63 - 100 mm. Stift und Bewegung in AISI 316, RADIAL

Angriff (ISO 228). Für d63: aus transparentem Polycarbonat,

Aluminium-Zifferblatt mit wei?em Hintergrund, Ma?stab BAR

schwarz und rot PSI (zwei Skalen Vakuummeter ausgeschlossen).

Genauigkeitsklasse 2,5 bis 1,6%, Aluminium Hand;Für d100:

transparent VSG, mit Zurückkappe Sicherheit, Skalierbarkeit

BAR, Genauigkeitsklasse 1,0% - hand Aluminium

Feineinslung.

Betriebstemperatur

Umwelt -30 / +65 ° C

Prozess -40 / +180 ° C

Betriebsdruck

Konstant 75% - Variable 60% - 25% überdruck bis 60 bar, mehr

als 15%

Varianten D63

Ma?stab normalisierten Vakuummeter -1 / 0 Bar+CmHg; Mano-Vakuummeter

-1+0,6; -1+1,5; -1+3; -1+5; -1+9; -1+15 nur

Bar; 0,6; 1; 1,6; 2,5; 4; 6; 10; 12; 16; 25; 40; 60; 100; 160; 250; 315;

400 Bar + Psi

Varianten D100

Ma?stab normalisierten -1 / 0; -1+0,6; -1+1,5; -1+3; -1+5; -1+9;

-1+15; 1; 1,6; 2,5; 4; 6; 10; 16; 25; 40; 60; 100; 160; 250; 400; 600;

1000; 1600 bar

Produkt-Optionen

Gewinde NPT ANSI B.1.20.1 mit oder ohne Glycerin, Entfetten

Verwendung Sauerstoff, Treppen Angriffen und/oder individuelle

Logos, farbige Einheiten, Sicherheitsglas (d100), l?uft

SOLID FRONT (d100), Abscheider (d100), elektrische Kontakte

(d100), 3/9/12 Stunden.

Manometri e vuotometri interamente in INOX

Gauges and vacuum gauges complete INOX MXX Manometer und Vakuummeter vollst?ndig Edelstahl

Konfit _ Fittings Solutions Disegni e dati tecnici non impegnativi ? Drawings and technical data not binding ? Zeichnungen und technische Daten unverbindlich | 269

fittings solutions

MXX 92 Manometri glicerina attacco radiale

Gauges liquid fillable bottom connection

Manometer Glycerin radial Angriff

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX926314099R 63 -1 ÷ 0 G1/4 CL1.6 1

MANOMETRI - GAUGES - Manometer

MXX926314Z06R 63 0 ÷ 0.6 G1/4 CL1.6 1

MXX926314001R 63 0 ÷ 1 G1/4 CL1.6 1

MXX926314106R 63 0 ÷ 1.6 G1/4 CL1.6 1

MXX926314205R 63 0 ÷ 2.5 G1/4 CL1.6 1

MXX926314004R 63 0 ÷ 4 G1/4 CL1.6 1

MXX926314006R 63 0 ÷ 6 G1/4 CL1.6 1

MXX926314010R 63 0 ÷ 10 G1/4 CL1.6 1

MXX926314016R 63 0 ÷ 16 G1/4 CL1.6 1

MXX926314025R 63 0 ÷ 25 G1/4 CL1.6 1

MXX926314040R 63 0 ÷ 40 G1/4 CL1.6 1

MXX926314060R 63 0 ÷ 60 G1/4 CL1.6 1

MXX926314100R 63 0 ÷ 100 G1/4 CL1.6 1

MXX926314160R 63 0 ÷ 160 G1/4 CL1.6 1

MXX926314250R 63 0 ÷ 250 G1/4 CL1.6 1

MXX926314400R 63 0 ÷ 400 G1/4 CL1.6 1

MXX926314600R 63 0 ÷ 600 G1/4 CL1.6 1

VUOTOMETRO - VACUUM GAUGE - Vakuummeter

MXX921012099R 100 -1 ÷ 0 G1/2 CL1.0 1

MANOVUOMETRO - COMPOUND - Manometer

MXX921012115R 100 -1 ÷ 1.5 G1/2 CL1.0 1

MXX921012903R 100 -1 ÷ 3 G1/2 CL1.0 1

MXX921012905R 100 -1 ÷ 5 G1/2 CL1.0 1

MXX921012909R 100 -1 ÷ 9 G1/2 CL1.0 1

MANOMETRI - GAUGES - Manometer

MXX921012Z06R 100 0 ÷ 0.6 G1/2 CL1.0 1

MXX921012001R 100 0 ÷ 1 G1/2 CL1.0 1

MXX921012106R 100 0 ÷ 1.6 G1/2 CL1.0 1

MXX921012205R 100 0 ÷ 2.5 G1/2 CL1.0 1

MXX921012004R 100 0 ÷ 4 G1/2 CL1.0 1

MXX921012006R 100 0 ÷ 6 G1/2 CL1.0 1

MXX921012010R 100 0 ÷ 10 G1/2 CL1.0 1

MXX921012016R 100 0 ÷ 16 G1/2 CL1.0 1

MXX921012025R 100 0 ÷ 25 G1/2 CL1.0 1

MXX921012040R 100 0 ÷ 40 G1/2 CL1.0 1

MXX921012060R 100 0 ÷ 60 G1/2 CL1.0 1

MXX921012100R 100 0 ÷ 100 G1/2 CL1.0 1

MXX921012160R 100 0 ÷ 160 G1/2 CL1.0 1

MXX921012250R 100 0 ÷ 250 G1/2 CL1.0 1

MXX921012400R 100 0 ÷ 400 G1/2 CL1.0 1

MXX921012600R 100 0 ÷ 600 G1/2 CL1.0 1

MXX921012M00R 100 0 ÷ 1000 G1/2 CL1.0 1

Codice/Code ? Scala (bar) Attacco “ Precisione

Range Connection” Accuracy

MXX990063 50-63 1